I have been out of industrial activity after completing my graduation for about 2 years, then RVS Quality Certifications Pvt Ltd has changed my outlook on my career. Adopting a course in NDT has helped me launch my career.

Why Is Phased Array Ultrasonic Testing Important for Pipeline Integrity

- By: Admin

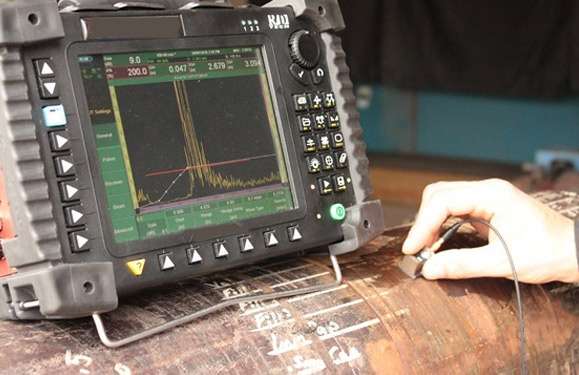

Pipelines are an important means through which oil, gas, and other fluids move long distances. Structural integrity to the pipelines helps prevent leaks and environmental dangers besides costly repairs. PAUT stands for Phased Array Ultrasonic Testing, a sophisticated and reliable technique for inspecting pipelines. By providing exact, comprehensive imaging of faults and abnormalities in pipeline constructions, this method has transformed non-destructive testing (NDT).

Improvement in Pipeline Flaw Detection

Accurate detection and size of flaws in conventional ultrasonic testing techniques is limited. But by combining many ultrasonic beams that can be electrically directed and concentrated, PAUT offers a significant increase. This feature improves the identification of weld flaws, corrosion, and fractures, therefore guaranteeing early identification of possible problems before they become major causes of failure. Different angles of scanning let inspectors get complete information on pipeline problems. This lowers the possibility of unnoticed defects, so inspections become more dependable and efficient. Better accuracy in detection provides room for preventative action, thereby prolonging the pipeline life and reducing the downtime.

Increased Efficiency in Inspections

PAUT also boasts of improved inspection speed compared to most others. It covers many angles in one scan, doing away with the need for a number of probes or repositioning. This not only saves time but also helps to lower the general inspection expenses. Efficiency is very vital for big-scale pipeline installations. Inspections delayed could cause financial losses and operational interruptions. Inspectors may cover more land in less time by using phased array technology while still preserving a high degree of precision. This makes it the ideal response for business operations that depend mostly on pipeline infrastructure.

Increased Interpreting and Visualising Data

Another significant advantage that PAUT has is the excellent imaging. PAUT produces high-resolution, real-time images, which make the identification of faults easier than conventional UT, that relies on A-scan data that requires great interpretation. Inspectors can rapidly and precisely make choices based on visual representations of flaws. Critical weld inspections, where exact flaw characterisation is crucial, benefit especially from this improved imaging capabilities. PAUT increases pipeline dependability even further by bettering data interpretation, hence lowering the possibility of misdiagnosis and needless repairs.

Adherence to Industry Standards

Strict guidelines imposed by regulatory authorities on pipeline inspection and maintenance guarantee environmental preservation and safety. By offering reliable, consistent inspection findings, PAUT enables businesses to satisfy these high standards. Phased array technology is acknowledged and supported for pipeline assessments in several industry standards including ASTM, ASME, and API. Using PAUT will help businesses show regulatory compliance and steer clear of legal hotpots related to pipeline leaks. This guarantees not just safety but also helps companies in the sector to be more credible and respectable.

Function of Tube Evaluation & Assessment Services

Apart from pipeline inspections, Tube Inspection Services offered by RVS Quality Certifications Pvt. Ltd., make use of phased array technology. In order to prevent leaks as well as breakdowns, all tube constructions and boilers need routine surveillance. Evaluating the tubing condition in most industrial applications by using PAUT is a powerful tool as the technology allows a detailed and exact imaging of it.

Instruction for Perfect Application

Effective PAUT maximises its advantages with appropriate training. To complement phased array examinations, inspectors must be highly knowledgeable in new technologies such Time of Flight Diffraction (TOFD). Phased Array and TOFD Training guarantees that experts can properly analyse data and carry out exhaustive inspections. Right training is essential for inspectors to enhance their knowledge, and it assists them in supporting more reliable, safer pipeline operations.

Securing Pipelines for a Safer Tomorrow

Pipeline systems, in reality, deserve high priority attention since the various industries rely on proper and safe fluid movement. PAUT has emerged as a potent inspection tool that has improved fault detection efficiency and compliance with the various industrial standards. This new technology will help companies proactively solve pipeline problems, reduce risks, and maintain a high degree of operating safety. Phased array technology will continue to be the pillar in the area of non-destructive testing as the demand for reliable infrastructure continues to increase.

RVS is the absolute best value to learn Aerospace NDT Training Course to nurture my skills. I am completely satisfied with how affordable the service they provide. Thanks RVS Team for constant support.

I would like to thank RVS for their time and patience in helping me learn and grow with my NDT courses. I was able to work and learn at the same time, with no pressure. I would recommend RVS to anyone seeking to work and take courses at the same time. I accomplished the course and today I'm a Certified PCN Level II UT engineer.

RVS helped our new hires to acquire the comprehensive training they need, as well as for refresher courses for our current employees. This has worked well for us in obtaining the necessary NDT certifications.

Just a few lines to express my gratitude for your outstanding service over the past year. We would have no issue in referring to your organisation because of your customer devotion and professionalism.

NDT is employed in a wide range of industries, including oil and gas, aerospace, energy, power, nuclear, and transportation, with nearly endless career opportunities. A job in NDT is extremely dynamic, and ongoing training is required.

One of the advantages of a four-year NDT programme is that students can study in a more focused and instructive manner. For graduates, this offers up a plethora of new NDT employment options, including quality assurance, management, engineering design, research, NDT training, and teaching.

Non-Destructive Testing (NDT) Training Courses - Levels 1, 2 and 3.

The PCN (Personnel Certification in Non-Destructive Testing) is a programme that meets the BS EN ISO 9712 requirements for NDT technicians and supervisors. It is founded in the United Kingdom, but it has an impact on a number of countries in the European Union.