I have been out of industrial activity after completing my graduation for about 2 years, then RVS Quality Certifications Pvt Ltd has changed my outlook on my career. Adopting a course in NDT has helped me launch my career.

Phased Array and TOFD Training

- By: Admin

NDT is very much involved in the industries of aerospace, oil and gas, construction, and manufacturing. It ensures the safety and reliability of critical structures by discovering any flaws in the materials without causing any damage to the structure itself. Phased Array and TOFD Training offered by RVS Quality Certifications Pvt. Ltd. have become two rare but highly advanced NDT techniques capable of detecting flaws with the utmost accuracy and efficiency.

Related Topics:

Phased Array Ultrasonic Testing

NDT Level 2 Certification Courses

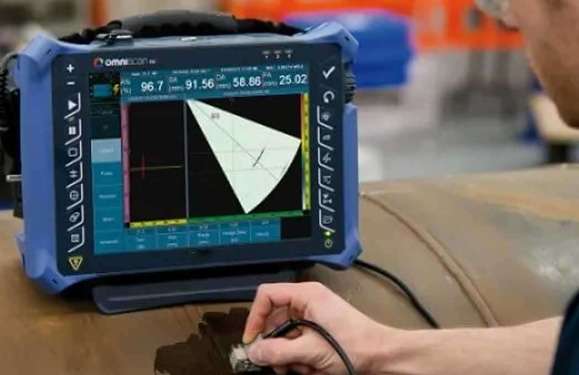

Phased Array Ultrasonic Testing (PAUT): The probe consists of multiple ultrasonic elements that could be electronically controlled to direct different beam angles. The image is then created with high resolution of the welds, pipelines, and structural components. Thus, this technique is extremely effective in detection of flaws.

Time of Flight Diffraction: This technique utilizes two ultrasonic probes, one acting as a transmitter and the other one as a receiver, that detect the presence of defects through diffraction signals. Hence, it is effectively used to find cracks and discontinuities in welded joints.

Key Advantages of Learning These Techniques

These advanced techniques provide a lot of assets to the benefit of NDT professionals if training is done to a proper extent.

- Enhanced Flaw Detection: Detailed images from PAUT and TOFD enhance the ability to detect the smallest imperfections that may appear in the working material.

- Greater Efficiency in Inspections: Unlike traditional ultrasonics, these methods enhance the pace and accuracy of assessment, which means that industrial operations enjoy reduced downtime.

- Less Human Error: Operators are not able to make mistakes as this is all put under automation by A-scan data being collected automatically, as well as enhanced to B-scan images.

- Wide Range of Skills: These methods find application in aerospace, power generation, pipeline inspection, etc., thus making trained professionals very valuable.

Industries That Stand to Benefit from Advanced Inspection Techniques

Different industries depend on PAUT and TOFD to ensure safety and sustain structural integrity. These state-of-the-art inspection methods function as the life-staving synapse in preventing failures and ensuring long-term reliability.

Aviation and Aerospace: In the aerospace industry, precision is a matter of life and death. The aircraft are rigorously inspected in search of hidden cracks, material fatigue, and corrosion that would affect safety. This advanced technology helps in the inspection of critical components such as wings, fuselages, and turbine blades, helping to minimize the possibility of failures in-flight.

Power and Energy Sector: Within the power sphere, especially nuclear, hydro, and thermal, plant stability is vested in components that are essential, such-so boilers, turbines, and pressure vessels. Testing methodologies can detect stress fractures, overheating damage, and early-stage defects, which will harm the efficiency and safety of the plant.

Heavy Machinery and Manufacturing : There are industries of manufacturing which include large-scale manufacturing, shipbuilding, and automotive production that require PAUT and TOFD for quality assurance and compliance with industry norms. These ensure that metal structures, weld joints, and mechanical components hold given safety and durability benchmarks to minimize operational risks and defect costs.

How Training Benefits NDT Professionals

With this advanced training in inspection technique, heightening an NDT professional's career will be a reality in not too distant future.

- Greater Employability: Most industries now seek their technicians trained in advanced techniques in ultrasonic testing, which increases their employment opportunities.

- Better Salary Opportunities: Skilled professionals savvy in PAUT and TOFD often receive high salaries due to the specialized knowledge.

- International Job Opportunities: The techniques of testing are globally used, so qualified professionals can get exposure at various international industries.

- Continuous Learning and Growing: Keeping abreast with emerging technologies in NDT keeps professionals ahead in the race of competitive industries.

The Future of NDT and Advanced Training

The burgeoning demand for professionals skilled in advanced inspection techniques will continue to grow as industries continue to emphasize safety and quality. Advancements like artificial intelligence and automation will further develop ultrasonic testing capabilities that will enhance the value of specialized training.

- Integration with AI and Robotics: Use of automated scanners and AI-driven analysis of data is making the process of depicting phenomena more accurate and more efficient.

- Increasing Demand of Industries: In stricter nations' regulations, the countries are more dependent on skilled NDT technicians.

- Broader New Applications: Developments in ultrasonic technology are proving to extend applicability of these methods beyond the traditional industries.

The Path to a Safer and More Efficient Industry

Mastering advanced inspection methods is more than just a career advantage—it is essential for ensuring industrial safety and reliability. By gaining expertise in high-precision flaw detection techniques, NDT professionals can contribute to preventing failures, protecting lives, and improving structural integrity. Investing in continuous learning and training today will lead to a stronger, safer, and more innovative future in the field of non-destructive testing.

RVS is the absolute best value to learn Aerospace NDT Training Course to nurture my skills. I am completely satisfied with how affordable the service they provide. Thanks RVS Team for constant support.

I would like to thank RVS for their time and patience in helping me learn and grow with my NDT courses. I was able to work and learn at the same time, with no pressure. I would recommend RVS to anyone seeking to work and take courses at the same time. I accomplished the course and today I'm a Certified PCN Level II UT engineer.

RVS helped our new hires to acquire the comprehensive training they need, as well as for refresher courses for our current employees. This has worked well for us in obtaining the necessary NDT certifications.

Just a few lines to express my gratitude for your outstanding service over the past year. We would have no issue in referring to your organisation because of your customer devotion and professionalism.

NDT is employed in a wide range of industries, including oil and gas, aerospace, energy, power, nuclear, and transportation, with nearly endless career opportunities. A job in NDT is extremely dynamic, and ongoing training is required.

One of the advantages of a four-year NDT programme is that students can study in a more focused and instructive manner. For graduates, this offers up a plethora of new NDT employment options, including quality assurance, management, engineering design, research, NDT training, and teaching.

Non-Destructive Testing (NDT) Training Courses - Levels 1, 2 and 3.

The PCN (Personnel Certification in Non-Destructive Testing) is a programme that meets the BS EN ISO 9712 requirements for NDT technicians and supervisors. It is founded in the United Kingdom, but it has an impact on a number of countries in the European Union.

-and-how-does-it-workwi3m.jpg)