I have been out of industrial activity after completing my graduation for about 2 years, then RVS Quality Certifications Pvt Ltd has changed my outlook on my career. Adopting a course in NDT has helped me launch my career.

How to Avoid Common Mistakes When Choosing Tube Inspection Services

- By: Admin

Choosing the right tube inspection services is essential for ensuring the safety and functionality of pipelines and tubular structures. With a range of advanced inspection techniques available—such as Phased Array Ultrasonic Testing (PAUT), Time of Flight Diffraction (TOFD) Training, and Infrared Thermography Services—it's vital to avoid common mistakes to ensure you select the best service provider. Here’s a guide to help you navigate the selection process effectively.

Understand Your Specific Inspection Needs

Accurately defining your inspection requirements is crucial when selecting Tube Inspection Services. Consider factors such as the material and size of the tubes, the operating environment, and the specific types of defects you aim to detect. A comprehensive understanding of these factors will guide you in choosing a provider equipped to meet your unique needs. By clearly outlining your inspection goals, you can avoid services that may not align with your requirements. This clear understanding ensures that the tube inspection services you select are tailored to your specific needs, preventing mismatches and ensuring the provider can effectively address your inspection objectives.

Prioritize Experience and Expertise

Opt for a service provider with a proven track record in your industry. Their experience in handling similar tube materials, sizes, and applications is invaluable. Additionally, RVS Quality Certifications Pvt. Ltd. has the necessary knowledge in advanced inspection methods such as Phased Array Ultrasonic Testing for more complicated inspections. A provider with a deep understanding of your industry's challenges can offer tailored solutions and insights. A provider with industry-specific experience is more likely to understand your challenges and provide effective solutions.

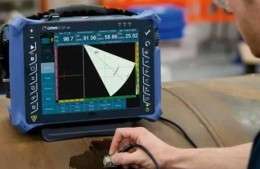

Invest in Advanced Technology

Modern inspection technology has significantly enhanced accuracy and efficiency. Seek providers equipped with cutting-edge equipment and software. Advanced data analysis capabilities enable early detection of potential issues, preventing costly equipment failures. Investing in a service provider that utilizes state-of-the-art technology ensures you benefit from the latest advancements in the field. Cutting-edge technology improves inspection accuracy, efficiency, and predictive capabilities.

Verify Certifications and Accreditations

Certifications and accreditations serve as indicators of a service provider's commitment to quality and adherence to industry standards. Look for recognized certifications such as ISO 9001, API, or ASME. These certifications validate the provider's competence and reliability, giving you confidence in their ability to deliver accurate and consistent results. Certifications and accreditations assure the provider's competence and adherence to quality standards.

Consider Total Cost of Ownership

While cost is undoubtedly a factor, focusing solely on the initial price can be misleading. A reputable service provider may offer slightly higher rates but delivers superior service, minimizing downtime and equipment damage. Evaluate the long-term benefits, including reduced maintenance costs and increased equipment lifespan. By considering the total cost of ownership, you can make a more informed decision that maximizes your investment. Evaluate the long-term benefits of a service provider, considering factors beyond the initial cost.

Build In-House Capabilities

Empowering your team with inspection knowledge is a strategic move. Partnering with a service provider that offers Phased Array and TOFD Training programs is crucial for developing in-house expertise. This training reduces reliance on external services, promotes self-sufficiency, and enhances your team's problem-solving abilities. Investing in Phased Array and TOFD Training can yield long-term benefits, including cost savings and improved operational efficiency. By building in-house inspection capabilities, you enhance your team's skills and reduce dependency on external providers, ultimately strengthening your overall inspection processes.

Leverage Advanced Inspection Techniques

Explore service providers offering advanced inspection techniques like infrared thermography. This non-destructive method complements traditional techniques by detecting heat variations associated with defects. You gain a comprehensive understanding of your equipment's condition by utilizing a combination of inspection methods. Advanced inspection techniques provide a more comprehensive assessment of equipment health.

Focus on Customer Support

A strong partnership with your service provider is essential for long-term success. Evaluate their responsiveness, communication skills, and problem-solving abilities. A reliable provider prioritizes customer satisfaction and builds relationships based on trust and collaboration. Effective communication and timely support are crucial for addressing challenges and ensuring project success. Effective communication and strong customer support are crucial for a successful partnership.

Selecting the right tube inspection service provider is a critical decision with far-reaching implications. By carefully considering these factors, you can avoid common mistakes and optimize equipment performance. Invest in a partner committed to quality, expertise, and customer satisfaction. A well-chosen inspection service provider can significantly impact equipment reliability and operational efficiency.

RVS is the absolute best value to learn Aerospace NDT Training Course to nurture my skills. I am completely satisfied with how affordable the service they provide. Thanks RVS Team for constant support.

I would like to thank RVS for their time and patience in helping me learn and grow with my NDT courses. I was able to work and learn at the same time, with no pressure. I would recommend RVS to anyone seeking to work and take courses at the same time. I accomplished the course and today I'm a Certified PCN Level II UT engineer.

RVS helped our new hires to acquire the comprehensive training they need, as well as for refresher courses for our current employees. This has worked well for us in obtaining the necessary NDT certifications.

Just a few lines to express my gratitude for your outstanding service over the past year. We would have no issue in referring to your organisation because of your customer devotion and professionalism.

NDT is employed in a wide range of industries, including oil and gas, aerospace, energy, power, nuclear, and transportation, with nearly endless career opportunities. A job in NDT is extremely dynamic, and ongoing training is required.

One of the advantages of a four-year NDT programme is that students can study in a more focused and instructive manner. For graduates, this offers up a plethora of new NDT employment options, including quality assurance, management, engineering design, research, NDT training, and teaching.

Non-Destructive Testing (NDT) Training Courses - Levels 1, 2 and 3.

The PCN (Personnel Certification in Non-Destructive Testing) is a programme that meets the BS EN ISO 9712 requirements for NDT technicians and supervisors. It is founded in the United Kingdom, but it has an impact on a number of countries in the European Union.